Production Units

Our production units offer quality and innovative solutions that stand out in the sector with the latest technology equipment and expert staff in the fields of machining, sheet metal forming and mold manufacturing.

Production Units

Measurement and Test Laboratory

“In our measurement laboratory, our parts and molds can be measured using a three-dimensional coordinate measuring device. In addition, even very small forms on the parts can be dimensionally controlled using a profile scanning device.

Surface treatment tests, metallographic examinations, surface and core hardness controls, welding macro tests can also be performed in our test laboratory.”

Production Units

Pres

“In our press department, sheet metal parts are shaped using C type mechanical presses from 160 tons to 200 tons, H type mechanical presses from 250 tons to 2500 tons and H type hydraulic presses from 350 tons to 2500 tons.

In our H-type mechanical machines, sheets up to 12 mm thick and 1300 mm wide can be fed as rolls and shaped in progressive molds.

Cutting and shaping of thick sheets can also be easily performed by using 630-ton and 800-ton narrow-table mechanical presses.”

Production Units

Machining

“In our machining unit;

- Indexers

- Revolvers

- Cylindrical grinding

- Lathes (CNC and Conventional)

- Vertical Machining Centers

circular and special cross-sectioned materials can be machined and thread extraction operations can be performed.

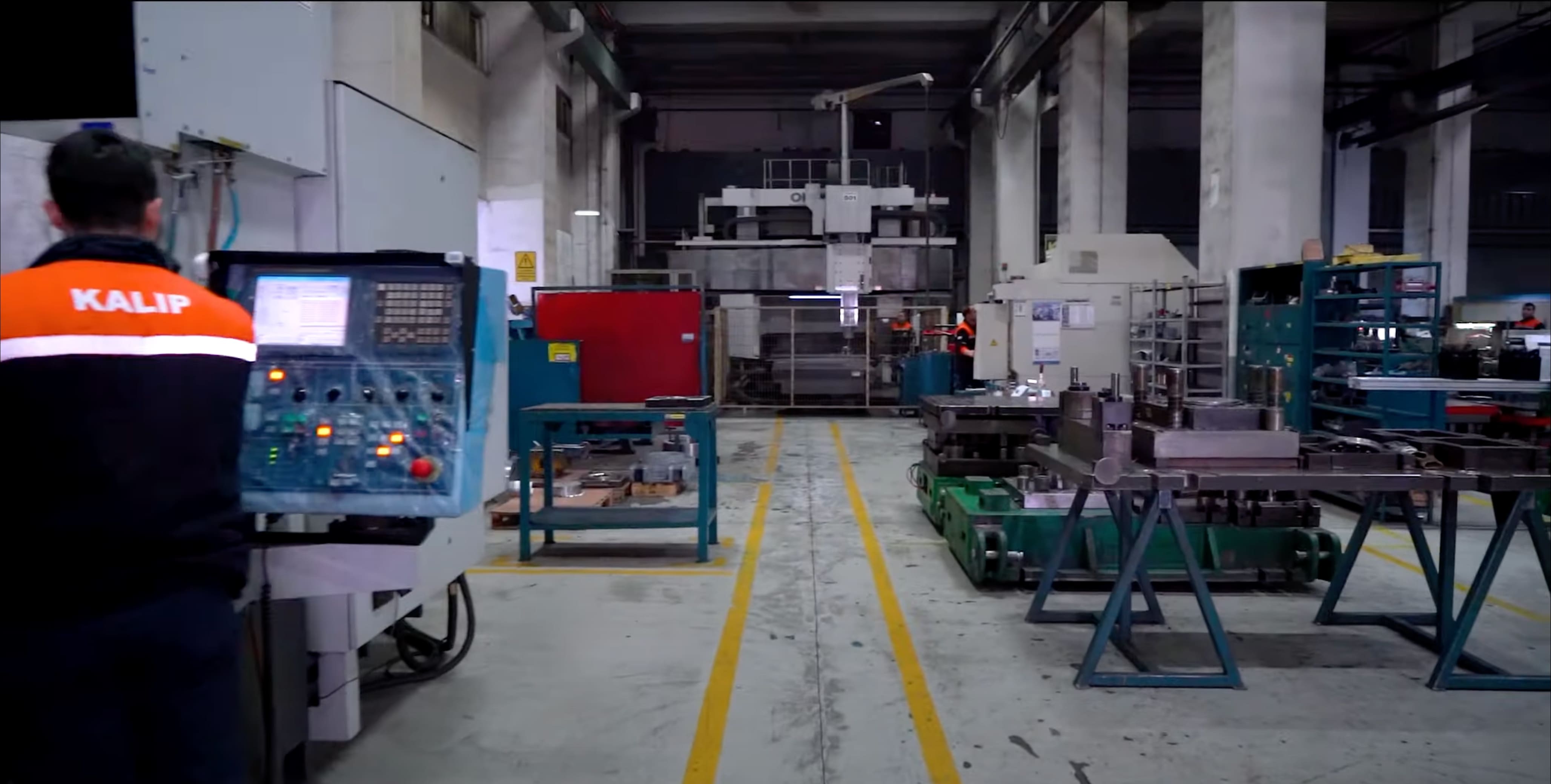

Production Units

Mold

In our mold production units, sheet metal forming molds up to 2000X4000 mm and up to 20 tons of weight can be manufactured using conventional molding machines as well as CNC machines with five axis and high speed machining capabilities.

All kinds of tandem sheet metal molds, transfer molds, progressive molds, deep drawing molds, production and control apparatus are produced in our company.

Production Units

Engineering

“As Şahince Automotive family, in our Engineering department, the processes of the products requested by our customers are determined and all mold/apparatus deliveries are made in-house with our strong and experienced engineer staff.

The work on the parts starts with determining the shape capabilities of the part by using finite element analysis. AUTO FORM software is used for these analyzes.

Mold/apparatus designs are made in Catia V6 program using 3D Experience PLM software. After design approvals, technical drawings and tool paths required for mold/apparatus manufacturing are created.

Şahince Automotive, which has an experienced staff to realize mold and production; tandem-prograsive-deep drawing-transfer molds as well as production and control apparatus are also produced.

Our project department continues to work within the engineering department to commission the products requested by our customers within Şahince Otomotiv.

All projects carried out during the new product commissioning process are initially planned using 3D Experience PLM/PDM software.

Later, when the Enovia PDM module is used for APQP and PPAP processes, change and revision management in documents, these processes are safely put into operation.”

Production Units

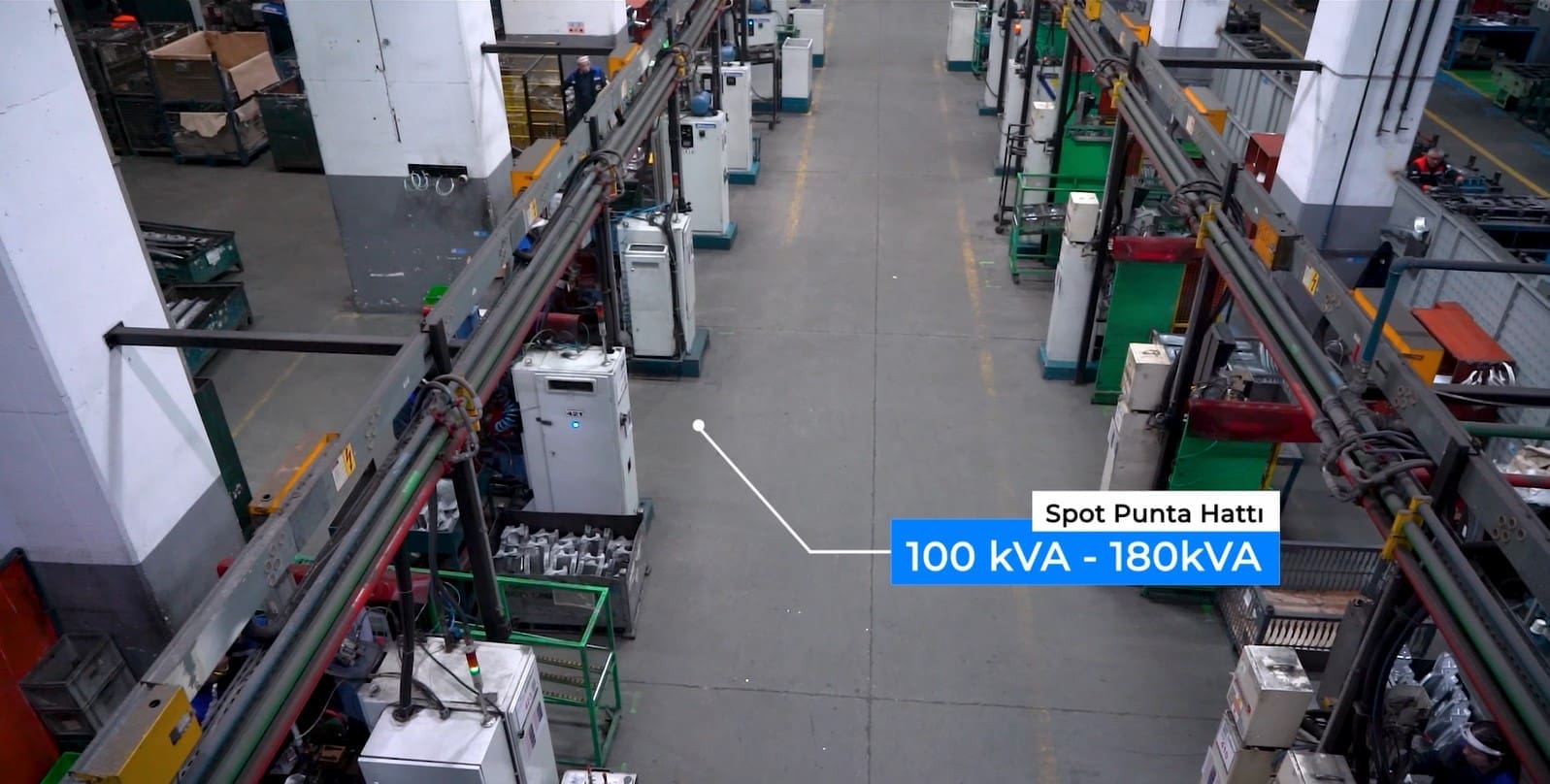

Source

Şahince company performs Mold, Apparatus, Welding Fixture, Press, Welding, Cataphoresis, Coating and Assembly processes under a single roof for its customers.

Our company responds to customer-specific needs in projection and resistance welding with the latest technology MFDC 100-180 KVA capacity spot/projection welding machines for the automotive sector.

We carry out the welding of difficult parts and safety parts with special welding forms under the control of our experienced employees in spot and gas welding robots and semi-automated rotary welding machines.

Production Units

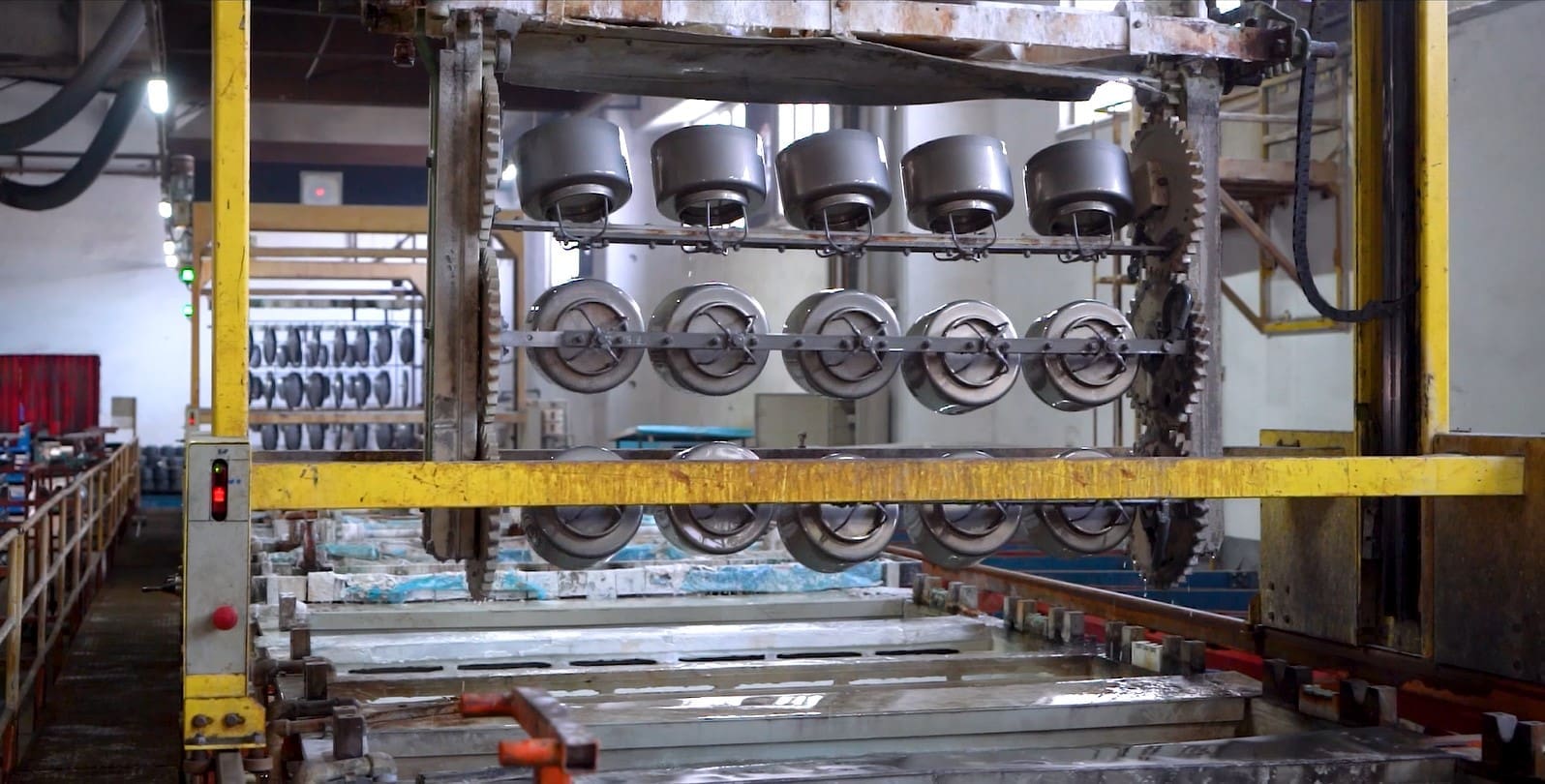

Cataphoresis

Our cataphoresis line consists of degreasing, activation, passivation, phosphate, cataphoresis and rinsing baths.

The process runs automatically. The film is controlled by voltage adjustment. Our cataphoresis plant is environmentally friendly. It does not pollute air and water. Our facility keeps its wastes under control in an environmentally friendly manner and sends them to treatment plants.

It aims to keep product quality always under assurance with detailed process analyzes. All kinds of tests of the parts leaving the plant are carried out in our laboratories.

Production Units

Coating

Our line, where alkaline zinc and zinc alloys are coated, includes loading, unloading, parking stations, coating baths and drying stations.

Our line is fully automated and the process is carried out according to product recipe programs.

Electro Zinc Plating is a general name given to the process of electrolytically coating a thin layer of zinc on iron and steel parts.

Electro Zinc Plating Processes

- Alkali Zinc Coating

- Passivation Types

- Cr+3 Blue/White Passivation

- Lacquer Types

- Organic Lacquer Types

- Inorganic Lacquer Types