Production Units

Our production units offer quality and innovative solutions that stand out in the sector with the latest technology equipment and expert staff in the fields of machining, sheet metal forming and mold manufacturing.

Production Units

MEASUREMENT AND TESTING

Measurement and Testing

In our measurement laboratory, our parts and molds can be measured using a three-dimensional coordinate measuring device.

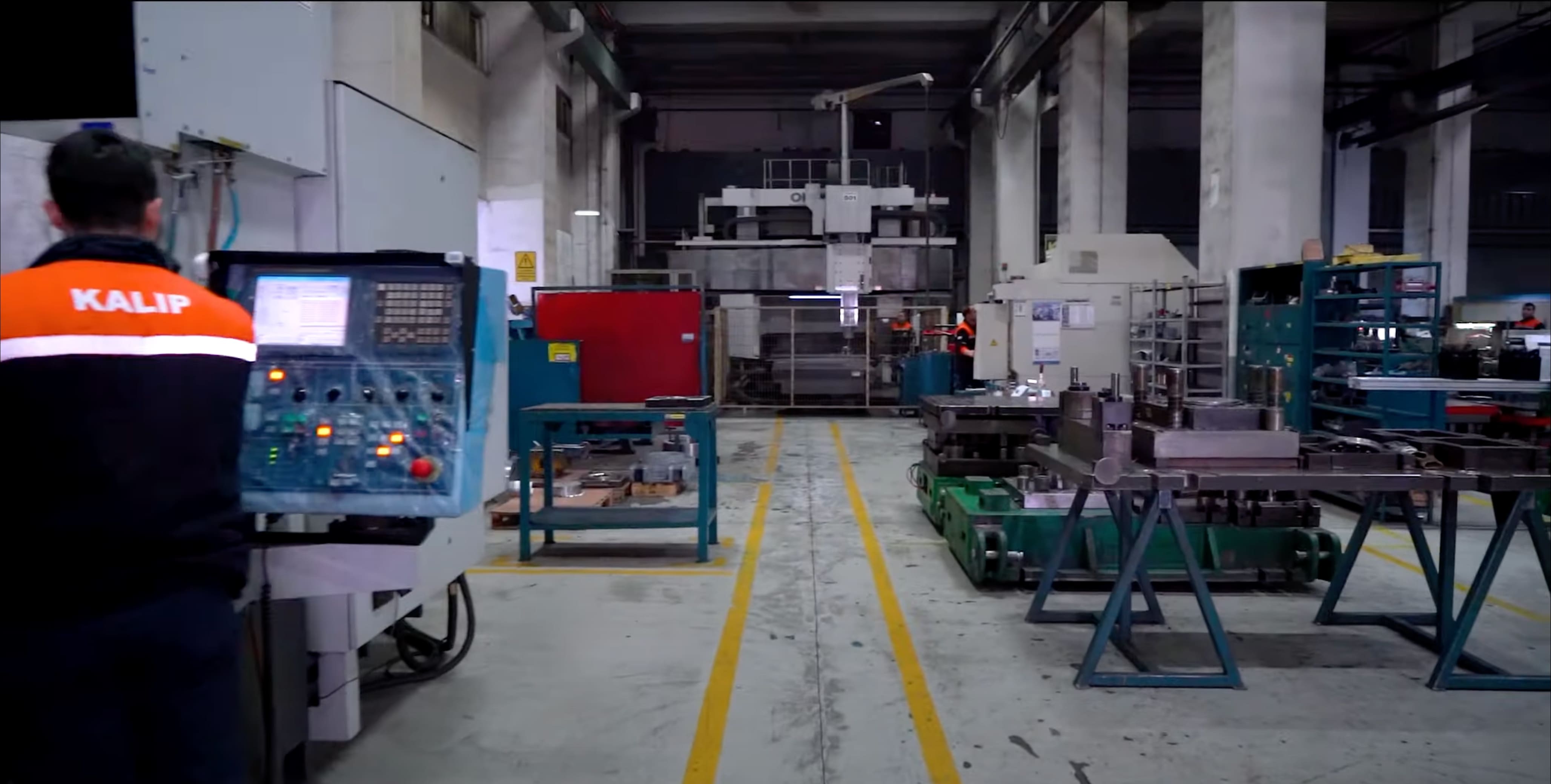

DetailENGINEERING

Engineering

As Şahince Automotive family, in our Engineering department, the processes of the products requested by our customers are determined and all mold / apparatus deliveries are made in-house with our strong and experienced engineer staff.

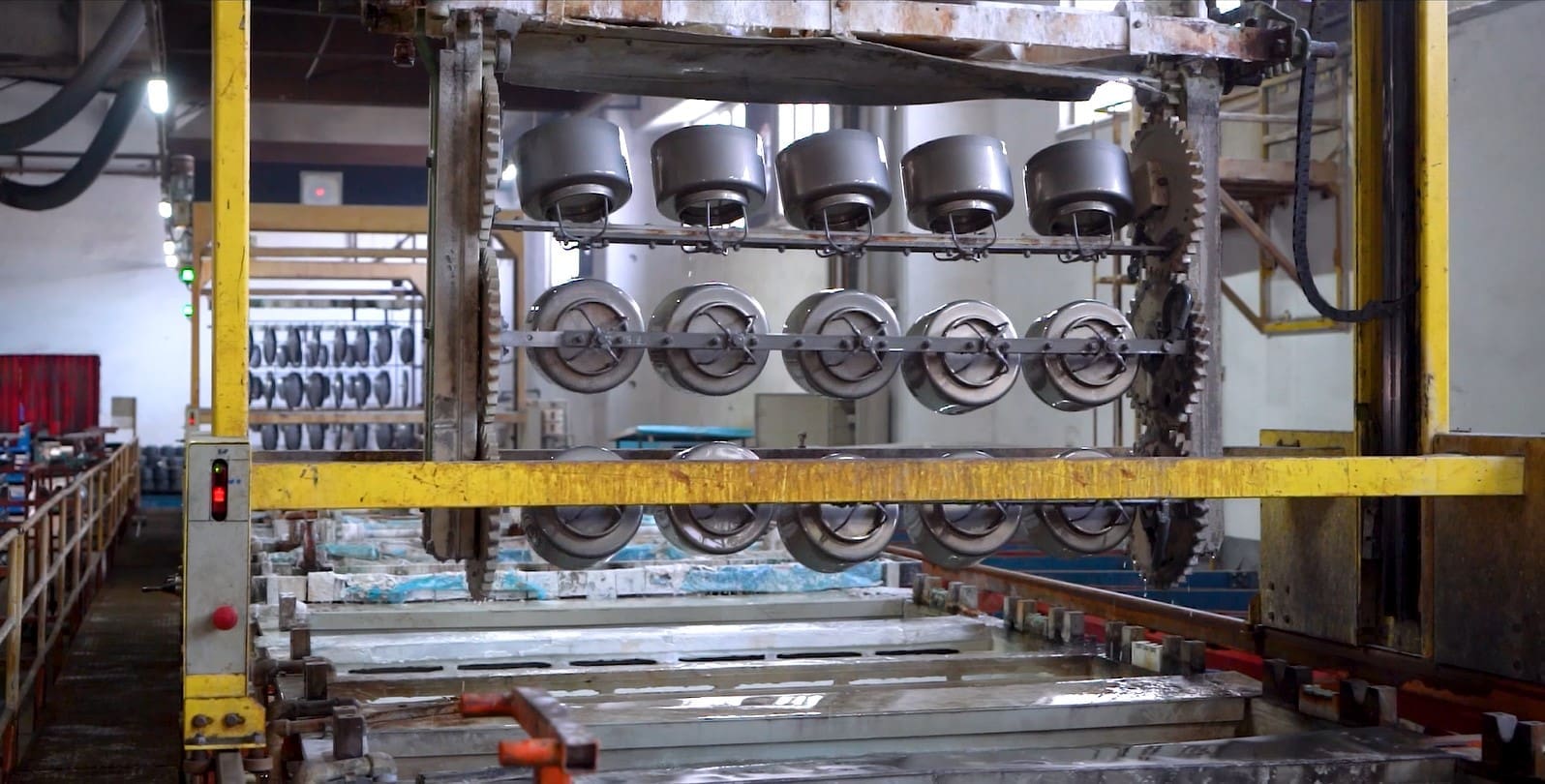

DetailCATAPHORESIS

Cataphoresis

Our cataphoresis line consists of degreasing, activation, passivation, phosphate, cataphoresis and rinsing baths.

Detail